Process Plant & Equipment

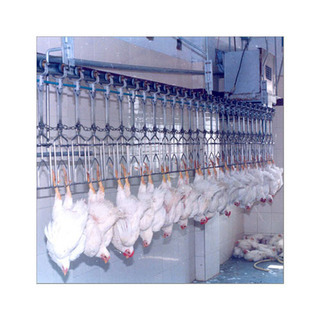

We are manufacturers and exporters of Processing Plants and specialized Process Equipment. Process Plants are developed as custom-built for client''s requirement & supplied as an Integrated unit on Turn-key basis. Process Equipment are fabricated as per client''s specifications & supplied as individual equipment. Our Process Plants are supplied for Agri. Processing sector covering Essential Oils and Aloevera. Poultry Processing sector and Chemical Process industries. Our plants are reputed for their Design, Process Technology, Quality, Consistant Performance and Customer Satisfaction.

Our Process Equipment are supplied to wide range of Process Industries which include - Chemical, Drugs & Pharmaceuticals Industries, Explosives & Paint manufacturing Industries, Food & Beverages industries, Wineries & Distilleries etc. Our Equipment are custom-built as per Process requirement or as per clients specifications. The Plants & Equipment are engineered in different metals like Stainless steel, Aluminium, Copper, Mild steel / Carbon steel etc. by adopting the best of manufacturing practices.

- Common Oils: Lemongrass, Citronella, Geranium, Palmarosa, Patchouli, Eucalyptus Oil etc,

- Floral: Rose, Kewda, Champa, Tuberose,

- Spices Oils: Ginger, Nutmeg, Cinnamon bark oil,

- Gum Resins: Frankinsence, Myrrh etc.

- Exotic Oils: Vetiver, Sandalwood, Agarwood oil.

Enquire Now

- Completely Integrated design

- Custom - built capacity from 1 Ton to 10 Tons

- Constructed from Superior Quality SS 304 or 316 grade Stainless Steel

- Low temperature processing

- Supply in Turn-key

- Highly effective owing to it's Quality and Purity

- Low maintenance

Enquire Now

Enquire Now

Our digestor based technology has been put to treat 3 different kinds of waste -

2. Layer Manure - Manure collected under the cages of layer birds in commercial poultry layer farms. This waste is converted into an organic fertilizer.

3. Slaughterhouse waste - Left over, non-edible portions of the chicken such as Head, feet, intestines, feathers, etc. from chicken processing. This waste is converted into a Meat and Bone meal.

13. Mulpuri Foods and Feeds Pvt. Ltd., AP

3. Carnes De El Salvador, El Salvador, S.America

Enquire Now

- Stable Grade Bleaching Powder Plants and

- Cardanol Resin Plant (Based On CNSl - Cashew Nut Shell Liquid)

Enquire Now

- Distillery Blenders

- Double Cone Blenders

- Double cone vacuum driers

- Stainless Steel Tanks

- Screw Conveyors

- Aluminum Tanks, etc.

These are fabricated as per client specifications by adopting advanced TIG and MIG welding technology. They are perfectly engineered to ensure optimum efficiency & reliability of operations even in the most demanding conditions.

Enquire Now