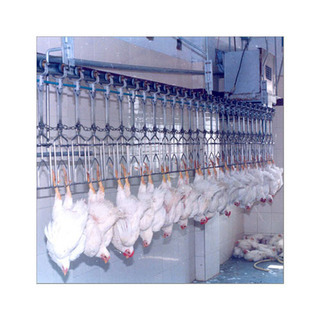

Conveyorised Chicken slaughter plant

Poultry Processing Plants are Conveyor - based chicken slaughter plants having an overhead conveyor and full range of process machines. The birds are dressed on the conveyor through all the important stages of processing such as stunning, halal, hot water scalding, de-feathering, evisceration & chilling etc. The conveyor based operations are scientifically designed machines ensuring the highest levels of hygiene providing the best quality of meat. They are designed for dressing capacities of 250 to 2000 Birds Per Hour (BPH).

Our Esteemed Clientele to whom we have supplied these plants to, in India, include:

1. Starchik Specialities Ltd., Hyderabad

2. Pioneer Farms Ltd., Hyderabad

3. Central Avian Research Institute, Bariely, U.P.

4. Kuljasrai Poultry Farms, Amritsar, Punjab

5. Goel Foods, Shimla, Himachal Pradesh

6. Swastic Supply Co., Ranchi -- ( Installed at Veterinary College, Kanke, Ranchi, Jharkhand )

We have also exported these plants to:

1. V.R. Equipments ltd., Pune – (for a Project located in Nigeria)

2. Kili Agro & Livestock Products , Tanzania

3. Dandani Farms Nigeria Ltd, Nigeria

4. Crown Agro Industries Ltd., Malawi

Enquire Now

Conveyorized Poultry Dressing Or Slaughter Plant

Poultry dressing or Slaughter Conveyor is a conveyor based Semi – Automatic Slaughter Plant. It is also known as slaughter plant. It consists of an overhead conveyor & other processing machinery. The birds are stunned, dressed and chilled in most scientific & most hygienic manner.

The dressing stages can be briefly categorized as:

• Stunning

• Bleeding

• Scalding

• De-feathering

• Evisceration (Internal Cleaning)

• Chilling

Features:

- Can be set up in a shed or building of 1500 to 3000 sqft.

- Scientifically designed to dress the bird in most Hygienic manner

- Adopts advanced engineering for semi automatic processing

- Covers All the stages from Stunning to Halal to Defeathering automatically

- Total stainless steel construction.

- Evisceration (Removal of internal body parts) is done manually.

Plant Capacities : 4,000 - 16,000 birds per day.

or

500 - 2,000 birds per hour.

Other Information

- Pay Mode Terms: L/C (Letter of Credit), T/T (Bank Transfer)

- Delivery Time: 10 to 14 weeks

Enquire Now

Electrical Stunner Machine

We offer a precision engineered range of Electrical Stunner machine that cater to the requirements of poultry industry. It is a device used in abattoirs to stun an animal in order to make it unconscious when it is bleed out. Robustly constructed, our electric stunner is ideal for small animals. Further, these can also be made as per the specific requirements of the clients.

Used for:

- It is a device used in abattoirs to stun an animal in order to make it unconscious when it is bleed out.

- Robustly constructed, our electric stunner is ideal for small animals.

Other Information

- Pay Mode Terms: L/C (Letter of Credit), T/T (Bank Transfer)

Enquire Now

Hot Water Scalder Conveyor Model

The hot water Scalder for Conveyorized plant are of Continuous type. They are made in different sizes suitable from 250 birds per hour to 2000 birds per hour capacity. Scalders have different heating and agitation options depending on capacity. They are made in stainless steel and play a crucial role in scientific & hygienic processing of poultry. These scalders have electronic controls for maintaining the temparature of water with in a close range.

Our scalders are efficient in scalding chicken in a clean, fast and easy manner. We can also customize these scalders in terms of temperature controls, agitation mechanism, design and capacity.

Features:

Its a conveyor based hot water scalder.

Offers scientific & hygienic poultry operations.

Efficient in scalding chicken in a clean, fast and easy manner.

It can be customized.

Offers scientific & hygienic poultry operations.

Efficient in scalding chicken in a clean, fast and easy manner.

It can be customized.

Other Information:

Pay Mode Terms: L/C (Letter of Credit), T/T (Bank Transfer)

Delivery Time: 12 to 18 weeks

Delivery Time: 12 to 18 weeks

Enquire Now

Feather Plucker machine for Conveyor plant

We manufacturer Feather Pluckers that are used by broiler farmers for poultry operations. De-Feathering machine or Feather Plucker as they are called is one the most important machine in Poultry Processing.

The Pluckers we make having four way adjustments for flexibility of plucking different sized birds from 1.0 kg to 3.0 kg (Live wt.). Made in food grade stainless steel, it has all the provisions for giving best feather plucking jointly with our Hot water Scalder. It also called as De-feathering machine.

The Feather pluckers are fitted with specially made food grade rubber fingers.

Features:

- Conveyor based feather plucker

- We offer four way adjustments for flexibility

- Plucking different sized birds from 1.0 kg to 3.0 kg (Live wt.).

- Specially made up of food grade rubber fingers.

Other Information

- Pay Mode Terms: L/C (Letter of Credit), T/T (Bank Transfer)

- Delivery Time: 12 to 18 weeks

Enquire Now

Screw Chiller for Chilling dressed bird

Screw Chillers are made of food grade stainless steel to suit the processing capacities from 2000 birds per day to 20,000 birds per day. This equipment is used to chill the bird after the process of scalding and de-feathering so that it can be made ready to be stored. On the request of our esteemed client, we also provide a Packaged Water Chiller to supply uninterrupted flow of Chilled water.

Features:

- Screw Chiller made in food grade stainless steel;

- It can process from 2000 birds to 20,000 birds per day.

This equipment is part of the Mini Processing unit consisting of Killing cones, hot water Scalder, Feather Plucker drum, Screw chiller, Drip Roller drum, Portioning machine & Vacuum packing machine etc. All the equipment / machineries are made in food grade stainless steel for maintaining most hygienic conditions in the meat processing area.

Other Information:

- Pay Mode Terms: L/C (Letter of Credit), T/T (Bank Transfer)

- Delivery Time: 12 to 18 weeks

Enquire Now

Hybrid Chicken Processing Plant

A fully conveyorized plant starts with loading of birds on conveyor trolley / shackles and ends with hock cutting to discharge the bird directly into a chiller.

The conveyor passes through different processing stages while birds are kept online throughout. Most of the processing is done automatically in special purpose machines and evisceration is done manually while bird is still on the conveyor shackle.

Hybrid plant uses some of the most important features of a conveyorized plant with mini processing equipment. It combines the use of conveyor and some equipment for Online processing with scalder and feather plucker kept Offline. The plant is custom built for increasing the adaptability of processing to get both the bird with skin as well as skinless birds while lowering the cost of installation.

Online processing;

Stunning, Halal, Bleeding, Neck removal, Hock (leg) cutter.

Offline processing;

Hot water scalder, Feather plucker, Evisceration.

Hybird Plant on stand -

Capacity : 1000 - 4000 birds per day.

Construction : Overhead conveyor, T Track with nylon Rollers, Non-rust Aluminium trolleys, Non-rust SS shackles, Driven by geared motor. Total Argon TIG welded.

Other Information

- Pay mode Terms: L/C (Letter of Credit), T/T (Bank Transfer)

- Delivery Time: 6 to 8 weeks.

Enquire Now

Non Conveyorised Dressing Equipment

The Mini processing plant is a setup of Non-conveyorized equipment specific for small and mid-sized dressing units. All the equipment is made in food grade stainless steel & built to the highest standard of engineering. They are convenient to set up and can be located at farms, market shops or at butchery's at larger establishments. The Stainless steel construction maintain excellent hygiene, low maintainance and long life for equipment.

The list of equipment include :-

- Killing Cone Table ( or Smaller Conveyor)

- Hot water Scalder

- Drum Plucker

- Work Tables and Evisceration Tables

- Screw Chiller

- Drip Drum

- Portion Cutter machine

- Packing horns

- Floor cleaner / washer

Details of each item is given in product list.

Plant Capacities : 200 - 2,000 birds per day.

Advantages of Mini plant;

- Easy to set up, Easy to maintain.

- Low power of consumption.

- Sturdy construction, Long life.

Other Information

- Pay Mode Terms: L/C (Letter of Credit), T/T (Bank Transfer)

- Delivery Time: 10 to 14 weeks

Enquire Now

Killing Cone Stand

Our killing Cone Stand comes in different capacities from 8 cones to 24 cones. The birds are placed in the cone & are allowed to bleed, halal while the shell rotates. This is part of poultry dressing machineries which can dress 500 to 2000 Birds Per Day (BPD).

Highlights or Features:

- Different capacities from 8 cones to 24 cones.

- It can dress 500 to 2000 BPD.

- Its a non-conveyor based processing equipment.

We manufacture complete range of Poultry Processing plant & machineries. These include :

- Poultry Processing plant with Conveyor for dressing of 500 to 1000 Birds Per Hour (BPH) i.e. 10,000 Birds Per Day (BPD).

- Poultry Processing Equipment ( with-out Conveyor) to process 500 to 2000 BPD.

- Rendering Plants for converting all the poultry waste into protein rich meat meal.

Other Information:

- Pay Mode Terms: L/C (Letter of Credit), T/T (Bank Transfer)

Enquire Now

Hot Water Scalder Drum Model

Hot water scalder is an important equipment in poultry slaughter house operations. It heats water & maintains it at suitable temperature continuously so that the Poultry Feathers are softened and removed during Plucking operations with out damaging the skin.

Our hot water scalder incorporates dual heating concept. It comes fitted with best quality electrical heaters along with provision for direct Gas burner under it. It is Robust but portable and comes with standard thermostat control for automatic temperature control. Scalders are supplied in different sizes as per processing needs. Our Scalders are provided with following standard fittings:

- A stainless steel Scalder Body in SS 304 with 2 or 3 Electrical Heaters;

- A Stainless steel Cage for loading and Lifting of Birds from Scalder;

- A Stainless steel Lifting Pole & Truss with V Pulleys, Bearings for Lifting SS Cage;

- A Electronic Control Box with Thermostats, 2 Contactors, Mcb, Digital Temp Controller etc;

- 2 Core, 4 mm sq. Heavy duty wires ( 3 x 10 ft each) for connecting Electrical heaters;

- Suitable wire for Thermostat connection;

- A heavy duty, Easy Lift Winch with SS handle to lift Cage with birds with just 6 turns;

- A Gas burner;

- A separate Gas Geyser for Hot water Intake during continuous Scalding;

- SS Flap for arresting Burner flame;

- Separate Cover Box to prevent water spillage on Electrical Heater.

The scalder can be heated by propane or bursh and gas in standby mode and switched to Electric Heating for proper temperature control.

Other Information:

- Pay Mode Terms: L/C (Letter of Credit), T/T (Bank Transfer);

- Delivery Time: 12 to 18 weeks.

Enquire Now

Feather Plucker - Drum Plucker

We manufacture Poultry Feather Pluckers ( also known as Drum Pluckers ) for use in removal of feathers during poultry processing. These pluckers are made in 2 different sizes - 23" diameter and 30" diameter. All pluckers have contact parts made entirely in SS 304 grade material for hygienic operations.

The 23" model is fitted with either 1.0 hp or 1.5 hp motor & V Belt & Pulley arrangement. The motors can be either Single phase ( 230 Volts) or Three phase ( 415 Volts) as required. This can process 5 to 6 birds at a time in a 3 minute cycle.

The 30" model is fitted with 2 or 3 hp motor with V Belt & Pulley OR with Gear Box arrangements. The 2 hp motor can be single phase but the 3 hp motors are in 3 phase. 2 hp model can process 10 to 12 birds at a time while 3 hp motor can process 15 to 20 birds at a time in a 3 minute cycle.

All the Pluckers come with following standard features:-

Excellent engineering design;

- Robust construction;

High in performance;

- Renders squeaky-clean birds with no pinfeathers;

- Processing is carried out in a scientific and hygienic manner with adjustable temperature.

The entire processing is carried out in the following stages:

- Killing

- Bleeding

- Hot water Scalding / Dunking

- Plucking

- Chilling and Dripping

Its a non-conveyor based poultry dressing equipment

Other Information:

- Pay Mode Terms: L/C (Letter of Credit), T/T (Bank Transfer);

- Delivery Time: Delivery on time.

Enquire Now

Portion Cutter Machine

Features:

- Completely Stainless Steel construction in SS 304 grade;

- "C" type sturdy body;

- 10 Inch SS Cutter Disc with safety flap;

- Disc mounted on SS shaft & SS Bearing Housing;

- V Pulley & Belt with guard;

- 1 HP motor ( Single phase or Three Phase ) with cover as required;

- Anti-Vibration pads;

- 1 year Warranty for Fabrication & All Material;

- Provided with Wooden Box for transport & Electrical Push button switch ( Optional);

Poultry dressing machineries cover a range of stand-alone equipments for dressing of poultry in non-conveyor mode. These includes killing cone stands having 8 to 24 cones, hot water scalder, feather plucker, portion cutter, screw chiller and drip roller, Work Tables, Evisceration Tables etc.

These machineries are required for Efficient dressing of poultry. These machineries are designed for dressing capacity of 500 to 2000 Birds Per Day (BPD).

Other Information:

- Pay Mode Terms: L/C (Letter of Credit), T/T (Bank Transfer);

- Delivery Time: Delivery on time.

Enquire Now

Lung Suction Gun

Lung suction gun removes the lung from inner cavity by vacuum suction. This operation removes lung as well as other residual matter inside the bird carcass.

Uses of Suction Gun:

Vacuum Lung Suction Gun used to remove lung as well as other residual matter inside the bird carcass.

Other Information

- Pay Mode Terms: L/C (Letter of Credit), T/T (Bank Transfer);

- Delivery Time: Delivery on time.

Enquire Now